Shape isn’t just a visual feature—it changes how things work. In the world of engineering and design, the shape of a component can mean the difference between success and failure. One such material, known as oilotgroblic, has raised questions due to its unusual form. Whether used in machine parts, tools, or experimental prototypes, oilotgroblic’s shape impacts how it performs under pressure, resists heat, or fits into other structures.

Understanding the shape of oilotgroblic helps engineers and designers create smarter, more efficient systems. This article explores what shape oilotgroblic usually takes, how it’s used, and what problems or benefits it brings in real-world applications.

Understanding the Shape of Oilotgroblic

How Is the Shape of Oilotgroblic Defined?

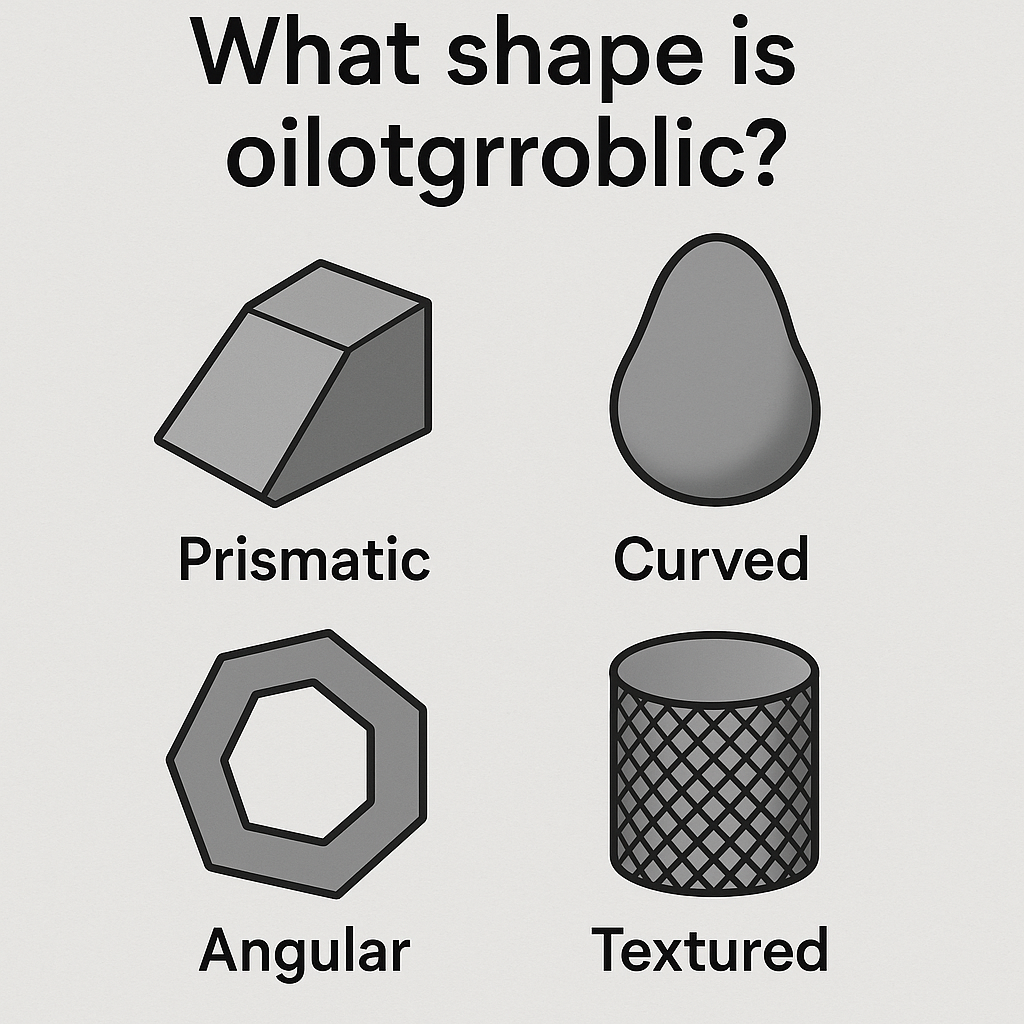

The shape of oilotgroblic is not standard. It depends on how and where it is used. In aerospace, for instance, the shape might be aerodynamic, almost like a teardrop, helping reduce drag. In manufacturing, it might look more like a hexagon or prism, offering strength without adding too much weight.

Each shape is made to match the environment it will work in. The material is adaptable, which is why oilotgroblic has no one-size-fits-all shape.

Why Does Oilotgroblic Have Unusual Geometry?

Unlike common materials, oilotgroblic often uses organic shapes—curves, rounded edges, or asymmetrical sides. These forms help improve stress flow, reduce tension points, and make the component more durable under repeated use.

The material also responds well to heat and vibration, so its shape can change slightly when conditions shift. That’s why some engineers design oilotgroblic with flexibility built into the form.

Materials That Affect Shape Design

The final shape of oilotgroblic depends on other materials it’s paired with. For example:

- Aluminum alloys: may require flat, panel-like oilotgroblic inserts.

- Carbon fiber: may call for curved designs that mold together seamlessly.

- Ceramics: need precise edges, so oilotgroblic may come in cube or triangle shapes.

Problems That Come From Misjudging Shape

Errors in CAD or 3D Modeling

Sometimes, designers use CAD tools (like AutoCAD or SolidWorks) that fail to capture the real shape of oilotgroblic. These tools can create sharp corners or straight lines, even though the material performs better with curves or slight bends. These mistakes often lead to fitting problems in the final build.

Fitment Issues in Assemblies

If oilotgroblic is shaped wrong, it may not fit where it’s supposed to go. This can cause:

- Mechanical stress on joints

- Misalignment in high-speed systems

- Leaks or air gaps in pressure-sensitive designs

Waste of Material and Time

Every time a shape needs fixing, it costs money. Cutting or molding oilotgroblic into the wrong form can waste valuable material. Plus, fixing these shapes means more hours in production, delaying delivery times.

Solutions for Shaping Oilotgroblic the Right Way

Using Simulation Software with AI

New design tools use AI algorithms to suggest the best shape for each job. For oilotgroblic, this could mean:

- Predicting stress zones

- Suggesting form tweaks based on temperature or pressure

- Improving durability through better geometry

AI also reduces human error and speeds up the modeling process.

Real-World Testing in Labs

Before finalizing the shape, many designers test oilotgroblic models using:

- Thermal cycling chambers

- Stress and load tests

- 3D printed prototypes

These methods reveal how the shape performs under real-life conditions.

Expert Input From Mechanical Engineers

Sometimes, tech isn’t enough. Human insight from experienced mechanical engineers still plays a major role. They can spot subtle problems in the shape, such as:

- Weak points in the design

- Improper flow or load paths

- Imbalance in the geometry

How Shape Affects Performance and Function

Load Distribution and Balance

Oilotgroblic is often used in rotating parts like turbines or drills. If its shape is off-center, it can throw off the whole system. Balanced shapes help:

- Distribute weight evenly

- Lower vibration

- Improve life span of parts

Thermal Performance and Shape

Shapes with curves or gaps allow heat to escape more easily. In hot environments like engine rooms, oilotgroblic performs best when shaped with air channels or open grooves.

Friction and Surface Contact

Some shapes reduce friction better than others. For example:

- Rounded shapes glide better across surfaces.

- Flat edges grip but may wear faster.

- Dimpled or textured forms reduce surface stickiness.

Choosing the right shape cuts down on wear and tear.

How Oilotgroblic Is Shaped in Manufacturing

Injection Molding and Shape Consistency

For mass production, injection molding is a go-to method. It allows consistent, repeatable shaping of oilotgroblic with minimal waste. This process is best when the shape needs tight tolerances or smooth finishes.

CNC Machining for Custom Designs

When custom shapes are needed, CNC machines offer high precision. They use data from CAD models to carve or trim oilotgroblic into complex forms. CNC is slow but ideal for prototypes and one-time builds.

3D Printing for Fast Shape Testing

3D printing, or additive manufacturing, is the quickest way to test new shapes. Engineers use this method to test how oilotgroblic behaves in different geometries before going full-scale.

Conclusion: Why Shape Defines the Role of Oilotgroblic

In the world of modern materials, the shape of oilotgroblic isn’t just a detail—it’s a defining feature. Whether it’s curved, flat, textured, or multi-angled, the form impacts performance, safety, and efficiency. Designers must understand how oilotgroblic reacts under stress, heat, and load to shape it right the first time.

With smart tools, expert advice, and proper testing, engineers can unlock the full potential of this unique material. Shape is not just what you see—it’s what drives how oilotgroblic works in real life.